Plant Tour

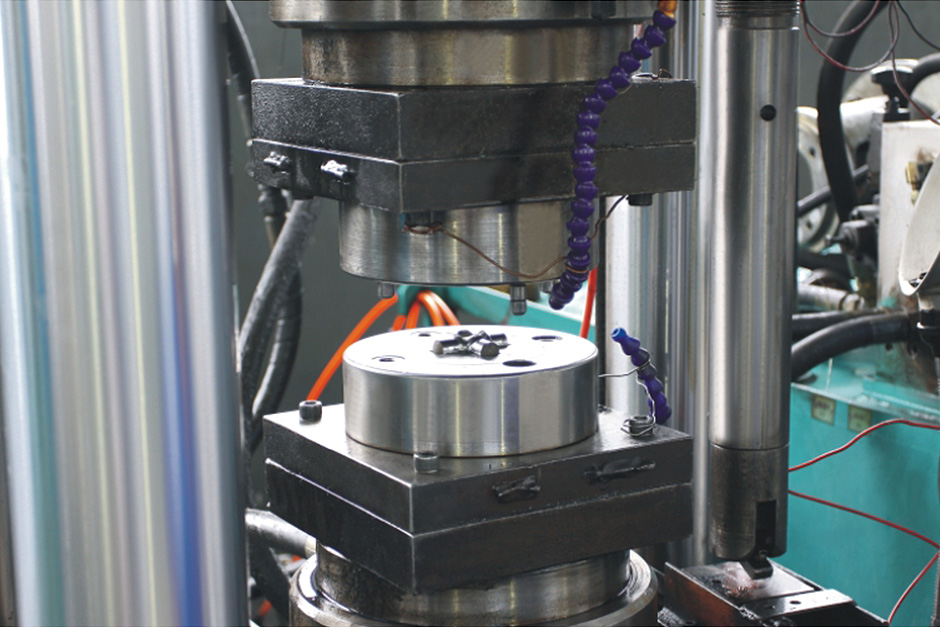

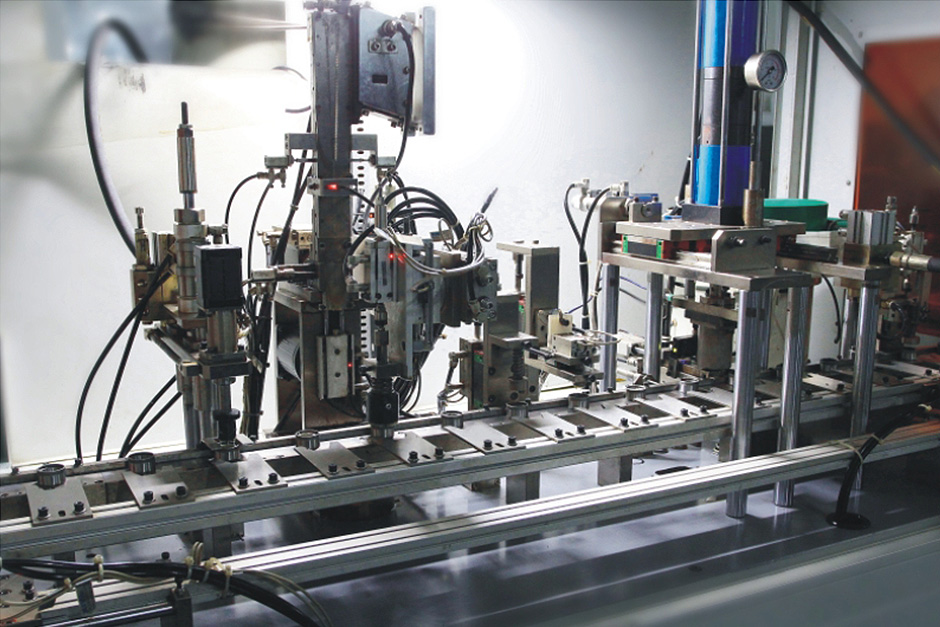

All the processes carried out on the products are strictly controlled and supported by documentation and all machinery is renewed according to latest

generation standards, giving priority to brands able to guarantee unfailing technical and software performance. The result for universal joint crosses

assemblies are machined to meet or exceed original equipment specifications. All parts are precision-ground to stringent tolerances with quality-control

inspections at every step of the manufacturing process.

KIMI KOTO U Joints also requires its suppliers to guarantee compliance and certification of both materials and semi-finished parts. Long-term cooperation with

the suppliers (all certified) has established the synergy required to improve our product and to promote continuous exchange of information regarding the development of new technologies.

Achievement of the Zero Defects target is guaranteed and maintained applying an organisational model that stimulates and motivates all KIMI KOTO personnel

andco-workers to constantly improve quality.

The modernized technique is pushing the social civilization ahead with incomparable speed and the unceasing innovation give the infinite vitality to

technology. KIMI KOTO just moved it step to world-wide market and over a long period, we have realized a leap for self development.

Now,KIMIKOTO can supply more than 1000 kinds of universal joints which applied in cars,suvs,trucks and construction machinery and so on. Most of universal

joints have ex-stock can be shipped in 3-5 days.